Chin Hung Supplies Foundry Equipment With High-Grade Components

Jan 15, 2004 Ι Supplier News Ι Machinery & Machine Tools Ι By Ben, CENS

Chin Hung Foundry Machinery Co., established in 1971, is one of Taiwan's major producers of metal-surface treatment machinery and whole- plant foundry equipment. The company develops its products with an emphasis on operator safety.

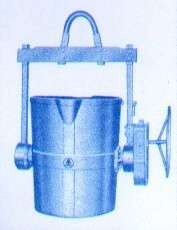

The stars in the firm's runway line-up of models are machines for metal-surface treatment and air- pollution abatement, shot-conveyor blasts, shot- hanger blasts, and apron-conveyor-type shot blasts, NLG geared-ladles and ladles for ductile cast-iron, and recycling, blending, and reclamation devices for organic self-hardening sand-molds. The company owns a 200-square-meter production facility in Taichung City, central Taiwan.

Since its establishment, the company has concentrated on developing state-of-the-art production equipment in cooperation with Japan- based Nippon Ladle Industries Co., a respected firm with a deep font of know-how in the development of various kinds of foundry equipment.

In addition to the acquisition of Japanese-created technologies, Chin Hung has also cultivated a team of technicians with systematic in-house training to ensure it continually upgrades its manufacturing skills as well as its product sophistication and quality. The result, it assures potential buyers, are products that help foundries and casting plants save production costs and upgrade their own manufacturing skills.

Chin Hung's main export market is mainland China, with some product delivered to Southeast Asian nations. Sales are made on both a single- unit and whole-plant basis. "We are capable of supplying whole-plant equipment because we have many veteran technicians to help buyers set up their production facilities; our related services extend from the planning through the installation stages," company president Chang Chun-yen says. "This includes know-how transfer to help them use our equipment to achieve maximum efficiency."

Chin Hung uses imported high-grade components and parts such as bearings to ensure the high quality of its products. "Because of the high-grade components, our ladles for ductile cast-iron, for example, are more durable than those made by producers in industrially developing nations," Chang claims. "Some of the latter type have a life span of only one year, while ours can last over 10 years."

For more information, contact the company at: 383-1 Tongying Rd., East Dist., Taichung City, Taiwan; Tel: 886-4-2211-5726/8; Fax: 886-4- 2211-5570; E-mail: ch.foundry@msa.hinet.net

The stars in the firm's runway line-up of models are machines for metal-surface treatment and air- pollution abatement, shot-conveyor blasts, shot- hanger blasts, and apron-conveyor-type shot blasts, NLG geared-ladles and ladles for ductile cast-iron, and recycling, blending, and reclamation devices for organic self-hardening sand-molds. The company owns a 200-square-meter production facility in Taichung City, central Taiwan.

Since its establishment, the company has concentrated on developing state-of-the-art production equipment in cooperation with Japan- based Nippon Ladle Industries Co., a respected firm with a deep font of know-how in the development of various kinds of foundry equipment.

In addition to the acquisition of Japanese-created technologies, Chin Hung has also cultivated a team of technicians with systematic in-house training to ensure it continually upgrades its manufacturing skills as well as its product sophistication and quality. The result, it assures potential buyers, are products that help foundries and casting plants save production costs and upgrade their own manufacturing skills.

Chin Hung's main export market is mainland China, with some product delivered to Southeast Asian nations. Sales are made on both a single- unit and whole-plant basis. "We are capable of supplying whole-plant equipment because we have many veteran technicians to help buyers set up their production facilities; our related services extend from the planning through the installation stages," company president Chang Chun-yen says. "This includes know-how transfer to help them use our equipment to achieve maximum efficiency."

Chin Hung uses imported high-grade components and parts such as bearings to ensure the high quality of its products. "Because of the high-grade components, our ladles for ductile cast-iron, for example, are more durable than those made by producers in industrially developing nations," Chang claims. "Some of the latter type have a life span of only one year, while ours can last over 10 years."

For more information, contact the company at: 383-1 Tongying Rd., East Dist., Taichung City, Taiwan; Tel: 886-4-2211-5726/8; Fax: 886-4- 2211-5570; E-mail: ch.foundry@msa.hinet.net

©1995-2006 Copyright China Economic News Service All Rights Reserved.