Auto Tools New Cars Mean New Opportunities For Taiwan's Hand-tool Makers

Mar 01, 2006 Ι Industry News Ι Hardware & Tools Ι By Quincy, CENS

Modern automotive technology has been advancing at a very high speed' and automakers have recently released more diverse car models to compete in the different niches of the global market. New cars' with different parts and unique sub-systems' are also developed over a much shorter period than before. All of these factors increase demands on repair and maintenance providers' and also increase the demand for special tools.

Taiwanese developers and manufacturers of automotive tools and equipment see an opportunity in this fast-developing market. Local tool makers are seeking to capitalize on the market's challenges with their strong R&D capabilities' prompt response times' ability to manufacture a large variety of items in small batches' and competitive prices.

They see the auto-tool market as a lucrative but high-threshold sector that requires more reliable products with more specific functionalities than the general hand-tool business.

Pullers' Sockets' and Hydraulic Jacks

One of these manufacturers is J&k International Co.' Ltd.' a leading fastening-tie supplier. J&K's products include hand-powered pullers' tie-downs' trailer winches' trailer jacks' tow ropes' and industrial safety belts.

J&K recently launched a new rope puller that features several advantages. First' the puller has an innovative mechanism that prevents tangling. Second' the model features easy operation' virtually unlimited reach' and is durable and strong. Third' the new model is quite versatile and is suitable for use with autos' boats' motorcycles' and other applications. Fourth' the puller is equipped with non-conductive polyester rope' which prevents scratching or scuffing. Fifth' the new puller is made of high-level' lightweight alloy steel and has an ergonomic design for operating convenience. Sixth' the model is easy to carry and store. Finally' the new puller is available with two optional' detachable handles: one has an ergonomic' bi-color design' while the other has a removable emergency light.

J&K is ISO 9001 approved' and the company's products are certified under major international safety and quality standards such as TUV' GS' and CE' demonstrating their high quality and reliability. Currently' the company has more than 50 patents in Germany' Canada' the U.S.' Taiwan' and mainland China.

Honiton Industries Inc.' established 26 years ago' is another Taiwanese manufacturer in the auto-tool industry. Honiton now supplies a very wide range of tools and related accessories' including sockets' extension bars' ratchet handles' universal joints' and socket-wrench sets.

Honiton claims that all of its products are made in Taiwan and that they strictly adhere to DIN standards. The company employs both stringent quality control systems and highly efficient management systems to ensure that it only makes top-grade tools. Honiton is also proud of its ability to roll out uniquely designed tools that meet the special requirements of customers around the world.

Tool Chests and Screw Drivers

Founded in 1987' Trimax Associates Co.' Ltd. Is a specialized developer and manufacturer of professional automobile hydraulic jacks and hydraulic lifting equipment for other industries.

In 1990' Trimax decided to shift part of its focus to Taiwan's domestic market. Since then' Trimax has been a major supplier of hydraulic jacks and other equipment to the island's subway construction projects. Trimax has also served as the local agent for a famous Japanese hydraulic equipment brand.

Trimax made a major decision in 1996 to begin producing pot bearings in cooperation with Cosmec Inc. of the U.S. Trimax claims that it now can produce pot bearings with a capacity of up to 3'600 tons.

In 1998' Trimax expanded its product line and began offering H-type and U-type heavy-duty hydraulic jacks for the construction industry. These products currently are exported to Japan and have won the approval of customers there. Trimax now claims that it has the ability to design and manufacture hydraulic jack equipment with a loading capacity of up to 700kg/square cm.

Trimax claims that it aims to become a major player in the international market. The company is willing to share its experience with partners worldwide and will provide custom-made products for clients with special requirements.

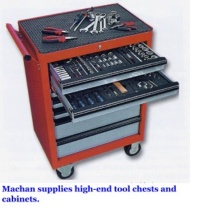

Machan Steel Furniture Co.' Ltd. Was established in 1975. In its early years' the company was a maker of steel office desks and furniture' and since then it has grown into a major Taiwanese developer and manufacturer of high-quality professional tool chests.

Machan's products are available to consumers under its SEQUOIA and BOXO own brands' and products are also provided on an OEM basis to many international brands.

Machan claims that it not only focuses on innovative design' but also on good craftsmanship. The ISO 9002-certified company claims that its products have both strong price competitiveness and high quality' making them the best choice for professional users.

Machan has an active product development team that monitors trends in the market' and then designs the company's state-of-the-art products according to the latest developments.

After it gained a solid foothold in making metal tool chests and cabinets' in 1988 Machan established a new subsidiary' the Jin Hsiang Plastic Industry Co.' Ltd.' to produce plastic blow-molded cases for export to the U.S. and European markets. In 1998' Machan set up the Changzhou Machan Industry Co.' Ltd. In Changzhou' Jiangsu Province' mainland China' to manufacture plastic toolboxes and tool sets. In 2002' the company also decided to begin manufacturing and selling steel toolboxes in China. In 2003' the company invested a large amount of money in new painting and inspection equipment for its plants on both sides of the Taiwan Straits.

Established more than 40 years ago' Yih Cheng Factory Co.' Ltd. Claims to be Taiwan's most experienced and specialized maker of professional screwdrivers and bits. In addition' the ISO 9001: 2000-certified company states that it has the most comprehensive product lines' the most advanced production techniques' the highest production capacity' and the best product quality among its counterparts on the island. Yih Cheng's products are covered by more than 30 patents worldwide.

Yih Cheng accepts OEM/ODM projects from customers from around the world' and the firm's Lancer tool brand is well known internationally.

The company claims its core competitiveness lies mainly in its 100% in-house development and manufacturing ability' which assures the highest quality for its tools. Yih Cheng says that it runs several in-house mold/die development workshops' where it adopts the most modern' integrated manufacturing equipment. The company's stringent quality-control system inspects the results of every production process. Yih Cheng also stresses that it has the world's most advanced tri-color' one-piece-formed plastic injection equipment and manufacturing techniques.

Yih Cheng claims that it also works relentlessly on using the latest materials for achieving high hardness and long product durability. The company uses the new SVCM special alloy steel to produce its screwdrivers and bits' making them more than 20% harder than counterparts made of S2 steel.

Taiwanese developers and manufacturers of automotive tools and equipment see an opportunity in this fast-developing market. Local tool makers are seeking to capitalize on the market's challenges with their strong R&D capabilities' prompt response times' ability to manufacture a large variety of items in small batches' and competitive prices.

They see the auto-tool market as a lucrative but high-threshold sector that requires more reliable products with more specific functionalities than the general hand-tool business.

Pullers' Sockets' and Hydraulic Jacks

One of these manufacturers is J&k International Co.' Ltd.' a leading fastening-tie supplier. J&K's products include hand-powered pullers' tie-downs' trailer winches' trailer jacks' tow ropes' and industrial safety belts.

J&K recently launched a new rope puller that features several advantages. First' the puller has an innovative mechanism that prevents tangling. Second' the model features easy operation' virtually unlimited reach' and is durable and strong. Third' the new model is quite versatile and is suitable for use with autos' boats' motorcycles' and other applications. Fourth' the puller is equipped with non-conductive polyester rope' which prevents scratching or scuffing. Fifth' the new puller is made of high-level' lightweight alloy steel and has an ergonomic design for operating convenience. Sixth' the model is easy to carry and store. Finally' the new puller is available with two optional' detachable handles: one has an ergonomic' bi-color design' while the other has a removable emergency light.

J&K is ISO 9001 approved' and the company's products are certified under major international safety and quality standards such as TUV' GS' and CE' demonstrating their high quality and reliability. Currently' the company has more than 50 patents in Germany' Canada' the U.S.' Taiwan' and mainland China.

Honiton Industries Inc.' established 26 years ago' is another Taiwanese manufacturer in the auto-tool industry. Honiton now supplies a very wide range of tools and related accessories' including sockets' extension bars' ratchet handles' universal joints' and socket-wrench sets.

Honiton claims that all of its products are made in Taiwan and that they strictly adhere to DIN standards. The company employs both stringent quality control systems and highly efficient management systems to ensure that it only makes top-grade tools. Honiton is also proud of its ability to roll out uniquely designed tools that meet the special requirements of customers around the world.

Tool Chests and Screw Drivers

Founded in 1987' Trimax Associates Co.' Ltd. Is a specialized developer and manufacturer of professional automobile hydraulic jacks and hydraulic lifting equipment for other industries.

In 1990' Trimax decided to shift part of its focus to Taiwan's domestic market. Since then' Trimax has been a major supplier of hydraulic jacks and other equipment to the island's subway construction projects. Trimax has also served as the local agent for a famous Japanese hydraulic equipment brand.

Trimax made a major decision in 1996 to begin producing pot bearings in cooperation with Cosmec Inc. of the U.S. Trimax claims that it now can produce pot bearings with a capacity of up to 3'600 tons.

In 1998' Trimax expanded its product line and began offering H-type and U-type heavy-duty hydraulic jacks for the construction industry. These products currently are exported to Japan and have won the approval of customers there. Trimax now claims that it has the ability to design and manufacture hydraulic jack equipment with a loading capacity of up to 700kg/square cm.

Trimax claims that it aims to become a major player in the international market. The company is willing to share its experience with partners worldwide and will provide custom-made products for clients with special requirements.

Machan Steel Furniture Co.' Ltd. Was established in 1975. In its early years' the company was a maker of steel office desks and furniture' and since then it has grown into a major Taiwanese developer and manufacturer of high-quality professional tool chests.

Machan's products are available to consumers under its SEQUOIA and BOXO own brands' and products are also provided on an OEM basis to many international brands.

Machan claims that it not only focuses on innovative design' but also on good craftsmanship. The ISO 9002-certified company claims that its products have both strong price competitiveness and high quality' making them the best choice for professional users.

Machan has an active product development team that monitors trends in the market' and then designs the company's state-of-the-art products according to the latest developments.

After it gained a solid foothold in making metal tool chests and cabinets' in 1988 Machan established a new subsidiary' the Jin Hsiang Plastic Industry Co.' Ltd.' to produce plastic blow-molded cases for export to the U.S. and European markets. In 1998' Machan set up the Changzhou Machan Industry Co.' Ltd. In Changzhou' Jiangsu Province' mainland China' to manufacture plastic toolboxes and tool sets. In 2002' the company also decided to begin manufacturing and selling steel toolboxes in China. In 2003' the company invested a large amount of money in new painting and inspection equipment for its plants on both sides of the Taiwan Straits.

Established more than 40 years ago' Yih Cheng Factory Co.' Ltd. Claims to be Taiwan's most experienced and specialized maker of professional screwdrivers and bits. In addition' the ISO 9001: 2000-certified company states that it has the most comprehensive product lines' the most advanced production techniques' the highest production capacity' and the best product quality among its counterparts on the island. Yih Cheng's products are covered by more than 30 patents worldwide.

Yih Cheng accepts OEM/ODM projects from customers from around the world' and the firm's Lancer tool brand is well known internationally.

The company claims its core competitiveness lies mainly in its 100% in-house development and manufacturing ability' which assures the highest quality for its tools. Yih Cheng says that it runs several in-house mold/die development workshops' where it adopts the most modern' integrated manufacturing equipment. The company's stringent quality-control system inspects the results of every production process. Yih Cheng also stresses that it has the world's most advanced tri-color' one-piece-formed plastic injection equipment and manufacturing techniques.

Yih Cheng claims that it also works relentlessly on using the latest materials for achieving high hardness and long product durability. The company uses the new SVCM special alloy steel to produce its screwdrivers and bits' making them more than 20% harder than counterparts made of S2 steel.

©1995-2006 Copyright China Economic News Service All Rights Reserved.