Taiwan Supplies Wide Variety of Sophisticated Plastic Processing achines

Jun 25, 2004 Ι Industry News Ι Machinery & Machine Tools Ι By Ben, CENS

The development of Taiwan's plastic-processing machine industry has its origins some four decades ago. Speedy growth, coupled with strong supporting factories, has led to a situation today where makers are capable of designing and producing a wide variety of sophisticated products in line with all special demands by purchasers.

Various large- and medium-sized manufacturers state they have made big strides in developing high-added-value products by elevating their machines' operating speeds, which help customers boost production with great cost-efficiency.

Over the past two decades domestic machinery manufacturers have been making focused efforts on penetrating the international market. Solid success has been enjoyed in the Southeast Asian market, and now some firms are saying they are as well enjoying success in the industrially advanced nations of North America and Western Europe. Some are quietly developing emerging markets in Eastern Europe and Central Asia in an effort to avoid the severe price competition that has arisen in the aforementioned markets.

According to the government-backed Plastics Industry Development Center (PIDC), manufacturers of domestic plastic-processing machines number over 250. Injection-molding machinery is the biggest segment, accounting for three-fourths of output in Taiwan, followed by extrusion machines with an approximately 25% share.

Statistics compiled by Taiwan's Directorate General of Customs under the Ministry of Finance (MOF), show that the island exported US$609.8 million worth of plastic-processing machines in the first 10 months of last year, up 10.5% from the US$580.22 million posted in the same period of the previous year. With the global economy showing clear signs of recovery since the beginning of this year, the Taiwan Association of Machinery Industry (TAMI) is predicting that exports of domestically made plastic-processing machines will continue to grow at a double-digit pace this year.

Always For Dah Customer

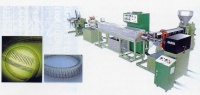

Founded three decades ago, For Dah Industry Co., Ltd. Is one of the leading manufacturers of whole-plant equipment for the production of PP/HDPE (polypropylene/ high-density polyethylene) woven bags, onion bags, cement bags, and HD/LDPE (high-density/low-density PE) blown-film-type bags.

For Dah began operations with the development of woven bag-making machines. Today it offers a wide variety of whole-plant equipment for the plastic-processing industry. The company will soon add printing machines to enrich its product line.

The ISO9001-certified company states that it has adopted computer-aided design and manufacturing (CAD/CAM). In addition, the company uses standardized parts and components to ensure the quality of its products.

With its research and development work focused on the long-term, and with advanced manufacturing capability and a strong commitment to customer services, For Dah has firmly established itself as one of the most reliable suppliers in the international marketplace.

The company's engineering department continuously seeks higher-quality production capability and better systems-control. The department is experienced in handling turnkey projects.

In addition to supplying high-quality machinery, For Dah also offers sophisticated manufacturing know-how to help customers obtain a competitive edge by incorporating more cost-effective production.

Although most domestic manufacturers in this line still focus on Southeast Asia for exports, For Dah has made inroads into the emerging markets of the Central Asia and Eastern Europe in the past five years. To boost sales to the Eastern European market, some four years ago the company established a representative office in Moscow.

"Since our establishment, we have been systematically striving to provide prompt after-sales services, " says Vivian Lee, export manager of For Dah. "The representative office in Moscow has really helped us boost sales to the emerging markets in Eastern Europe and Central Asia. For instance, we have 90% market shares in such emerging markets as Turkmenistan, Kazakhstan, Lithuania, Latvia, and even Mauritius."

Lee says her company offers prompt after-sales services to customers even in remote areas. "We have close ties with overseas specialists and sales agents, " Lee notes. "But we view after-sales services as the last component in an unbroken line, even though we always give priority to the production of high-quality machines which need little repair and maintenance."

The company is now considering the setting up of a representative office in Panama to extend prompt after-sales services to Latin American customers.

For Dah states that it imports high-quality parts and components, including electronic control systems and motors, from such industrially advanced nations as Germany and Japan to ensure the quality of its products, and says that all its products have to pass strict inspection and trial runs before they are shipped.

Over the past several years, the company has been striving to develop new models to meet customers' changing needs. One of the company's most innovative new products is a gusseting & rotating machine which is suitable for the production of PP/HDPE woven bags and laminated bags. Management says the machine is unique in Taiwan because it can print lettering in the middle of the gusset of the woven bag.

Hao Yu Found Round the Globe

Another manufacturer providing whole-plant equipment for the production of PP woven bags is Hao Yu Precision Machinery Industry Co., which was established in 1980 in Taichung County, central Taiwan.

An ISO9002-certified manufacturer that in addition carries the CE mark, Hao Yu also specializes in providing geo-textile and wood/plastics composite products. The company says it is capable of rolling out a variety of machines for the production of low-denier foodstuff bags and high-denier woven bags.

The company's major product lines include twelve-shuttle jumbo circular looms, PP woven inner linear-inside lamination machines, flat-yarn high-speed extrusion machines, and wood/plastics composite extruding machines.

Hao Yu boasts it has exported whole-plant equipment to over 50 nations. Major export outlets include the Middle East, Africa, the Arabian peninsula, and Thailand. Recently the company has received an order for PP woven-bag whole-plant equipment from Zambia, which will be delivered at the end of April. The company will dispatch three well-trained workers to Zambia to help its customer install the equipment and launch trial-run operations.

The company focuses on the production of high-end products and innovative high-added-value machines. "Our PP woven-bag machine produced bags with tension-resistance five times stronger than those made by rival domestic producers, " says Hao Yu president Chi Ching-yao. "Because of our persistence in producing high-quality products, over the past several years we have won many government bids in our home market."

The company says it has a five-person in-house R&D department in charge of developing its innovative machine models. "In addition to developing brand-new models featuring sophisticated functions, we also pay much attention to the quality of our products in every detail. For instance, we import expensive bearings from industrially advanced nations."

Chi says his company has won a solid reputation for the production of plastic woven-bag machines in the international marketplace. "Our machines have proven reliability, and many customers say they are still using the machines we produced some two decades ago, " Hao boasts. "Thanks to this reliability, we have established such good relations with customers that they often help us find new clients."

Recently the company has been concentrating on the development and production of environment-friendly machines that are capable of producing woven-plastic materials used in protecting hill slopes from collapse.

Hao Yu's wood/plastics composite extruding machinery is one of the company's best-selling product lines. The machine can extrude wood/plastic composite decorative trims for home furnishing industry. "The decorative trims are moisture- and fire-proof, " says Chi. "Seeing the promising prospects of the composite decorative trims, we have alloted a section of our production facility to roll out the promising products by way of our machines.

The company boasts the woven-plastic materials produced with its machines have passed stringent inspection and testing from academic units, including National Taiwan University of Science and Technology, National Pingtung University of Science and Technology, and Chung Yuan Christian University.

Tai Shin a Name That Means Quality

Specializing in the production of extrusion lines and pelletizing equipment, Tai Shin Plastic Machinery Co., Ltd. Is focusing on price-competitive machines, rather than expanding product lines.

At present Tai Shin's major product lines include extrusion lines for flexible hoses reinforced with spiral yarn inserts, PVC (polyvinyl chloride) pelletizing plants, co-extrusion lines for soft-rigid spiral-wound pipes, twin-screw extrusion lines for PVC pipes and profiles, and extrusion lines for spring-wire hoses.

The co-extrusion line can produce soft-rigid spiral-wound pipes of two inches in inner diameter. "The machine is capable of rolling out 1.5 meters per minute, three times faster than the same model produced by other domestic manufacturers, " boasts Tai Shin general manager Gordon Chang.

To keep products at a high-level quality standard, the company imports top-grade parts and components from industrialized nations. The company has an in-house R&D department to develop innovative products. For instance, the company boasts its extrusion line for spring-wire hoses is unique in Taiwan. "The line is capable of producing one-piece spring-wire enhanced hoses without worrying about fracture, " says Chang.

At present the company exports 90% of its output to overseas markets, including Brazil, Argentina, Egypt, Saudi Arabia, the Middle East and Southeast Asia.

Chang boasts his company has received orders to fill production lines up to the end of July. "I estimate our sales for the entire year will grow by over 30% from last year's level because of the global economic recovery, " says Chang.

Chang says his company won't pursue expansion of quantity but quality. "It's meaningless for us to expand production capacity because we are small in size, " explains Chang. "But we will put more emphasis on producing high-quality and innovative products to draw customers' attention from the world over."

Recently the company has been speeding up the pace of development of its corrugated pipe-extrusion line, which it intends to introduce to the international marketplace in the middle of this year. Prototypes were on display at the Taipei International Plastics & Rubber Industry Show staged March 18-21 at the Taipei World Trade Center.

A Name to Remember

Jing Fang Machinery Co., Ltd., established 16 years ago, specializes in the production of high-efficiency, high-precision, and user-friendly plastic-processing machines.

The company's major product lines include laminating machines, and rotogravure printing presses (2-12 colors or 4-8 colors). The company boasts it is capable of rolling out two printing presses in three or four days.

With an in-house research and development department, Jing Fang concentrates on developing innovative products to meet customers' special demand. The company mainly exports its machines to Southeast Asia and mainland China, in addition to domestic sales.

"Since our establishment, we have been making all-out efforts to upgrade our machines by elevating the operating speed so that they can perform with high efficiency, " says Dein Huang-yu, president of the company.

The company's laminating machine is applicable for such materials as PP, PE, cellophane, aluminum foil, and paper. Maximum machine velocity reaches 200 meters per minute.

Although some developing nations such as mainland China have begun production of plastic processing machines, Dein says his company has no fear of it and will continually develop more sophisticated products to get rid of price competition from the newcomers of the developing nations.

The company boasts its machines are equipped with high-precision electric systems imported from Japan. "The state-of-the-art electric systems make our machine do such precise operations as material feeding and cutting, " Dein says.

Wei Sheng Crushes the Competition

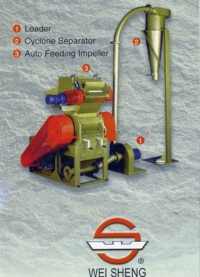

Wei Sheng Machinery Industrial Co., Ltd., founded in 1991, specializes in the production of powerful, quiet-running crushing machines. The company boasts it is capable of rolling out quite a lot of peripheral equipment for the plastic processing machines.

With over a decade of development, the company has developed many practical machines to fit the need of the plastic processing industry, including silent granulator, claw-tool-type muffing crushing machine, instant crushing and recycling machine, waste recycling devices for vacuum forming products, universal powerful crushing machine, double-axle strong shredder, and vertical mixing blender.

With a workforce of 15, Wei Sheng is capable of rolling out 20 crushing machines per month. "Although our machines are medium and small in size, they are a must-to-buy item for the plastic processing machines, " says company president Lee Ta-wei.

Lee says his company has paid much attention to elevate the safety degree of the machines in operation. For instance, the company's muffing crushing machine is equipped with a safety device that can automatically stop the machine when it is improperly operated.

The company says its products are mainly sold to overseas markets, including the Middle, Southeast Asia and Europe.

Contact information on companies covered by the article:

1.

Hao Yu Precision Machinery Industry Co.

Address: No. 290, Haiwei Rd., Chungher Village, Lungching Hsiang, Taichung Hsien, Taiwan.

Tel: 886-4-2630-3998

Fax: 886-2630-1410

Website://www.green-tec.com.tw

E-mail: haoyu@ms12.hinet.net

2.

Tai Shin Plastic Machinery Co.

Address: No. 27, Chungcheng Rd., Minhsiung Industrial Park, Chiayi Hsien, Taiwan.

Tel: 886-5-213-2233

Fax: 886-5-213-2231

Website://tspm.com.tw

E-mail: tspm@ms14.hinet.net

3.

For Dah Industry Co.

Address: No. 48, Chungshan Rd., Minhsiung Industrial Park, Chiayi Hsien, Taiwan.

Tel: 886-5-221-5139

Fax: 886-5-221-9259

Website://fordah.com.tw

E-mail: fordah@ksts.seed.net.tw

4.

Jing Fang Machinery Co.

Address: No. 30, Lane 221, Jenhwa Rd., Tali, Taichung Hsien, Taiwan.

Tel: 886-4-2491-0016

Fax: 886-4-2491-0013

E-mail: jing.fang@msa.hinet.net

5.

Wei Sheng Machinery Ind. Co.

Address: No. 3, Alley 36, Lane 64, Tzuchiang 3rd., Wuchi, Taichung Hsien, Taiwan.

Tel: 886-4-2639-9998

Fax: 886-4-2639-3618

E-mail: breaker@ms23.hine.net

Website://www.weisheng.com.tw

Various large- and medium-sized manufacturers state they have made big strides in developing high-added-value products by elevating their machines' operating speeds, which help customers boost production with great cost-efficiency.

Over the past two decades domestic machinery manufacturers have been making focused efforts on penetrating the international market. Solid success has been enjoyed in the Southeast Asian market, and now some firms are saying they are as well enjoying success in the industrially advanced nations of North America and Western Europe. Some are quietly developing emerging markets in Eastern Europe and Central Asia in an effort to avoid the severe price competition that has arisen in the aforementioned markets.

According to the government-backed Plastics Industry Development Center (PIDC), manufacturers of domestic plastic-processing machines number over 250. Injection-molding machinery is the biggest segment, accounting for three-fourths of output in Taiwan, followed by extrusion machines with an approximately 25% share.

Statistics compiled by Taiwan's Directorate General of Customs under the Ministry of Finance (MOF), show that the island exported US$609.8 million worth of plastic-processing machines in the first 10 months of last year, up 10.5% from the US$580.22 million posted in the same period of the previous year. With the global economy showing clear signs of recovery since the beginning of this year, the Taiwan Association of Machinery Industry (TAMI) is predicting that exports of domestically made plastic-processing machines will continue to grow at a double-digit pace this year.

Always For Dah Customer

Founded three decades ago, For Dah Industry Co., Ltd. Is one of the leading manufacturers of whole-plant equipment for the production of PP/HDPE (polypropylene/ high-density polyethylene) woven bags, onion bags, cement bags, and HD/LDPE (high-density/low-density PE) blown-film-type bags.

For Dah began operations with the development of woven bag-making machines. Today it offers a wide variety of whole-plant equipment for the plastic-processing industry. The company will soon add printing machines to enrich its product line.

The ISO9001-certified company states that it has adopted computer-aided design and manufacturing (CAD/CAM). In addition, the company uses standardized parts and components to ensure the quality of its products.

With its research and development work focused on the long-term, and with advanced manufacturing capability and a strong commitment to customer services, For Dah has firmly established itself as one of the most reliable suppliers in the international marketplace.

The company's engineering department continuously seeks higher-quality production capability and better systems-control. The department is experienced in handling turnkey projects.

In addition to supplying high-quality machinery, For Dah also offers sophisticated manufacturing know-how to help customers obtain a competitive edge by incorporating more cost-effective production.

Although most domestic manufacturers in this line still focus on Southeast Asia for exports, For Dah has made inroads into the emerging markets of the Central Asia and Eastern Europe in the past five years. To boost sales to the Eastern European market, some four years ago the company established a representative office in Moscow.

"Since our establishment, we have been systematically striving to provide prompt after-sales services, " says Vivian Lee, export manager of For Dah. "The representative office in Moscow has really helped us boost sales to the emerging markets in Eastern Europe and Central Asia. For instance, we have 90% market shares in such emerging markets as Turkmenistan, Kazakhstan, Lithuania, Latvia, and even Mauritius."

Lee says her company offers prompt after-sales services to customers even in remote areas. "We have close ties with overseas specialists and sales agents, " Lee notes. "But we view after-sales services as the last component in an unbroken line, even though we always give priority to the production of high-quality machines which need little repair and maintenance."

The company is now considering the setting up of a representative office in Panama to extend prompt after-sales services to Latin American customers.

For Dah states that it imports high-quality parts and components, including electronic control systems and motors, from such industrially advanced nations as Germany and Japan to ensure the quality of its products, and says that all its products have to pass strict inspection and trial runs before they are shipped.

Over the past several years, the company has been striving to develop new models to meet customers' changing needs. One of the company's most innovative new products is a gusseting & rotating machine which is suitable for the production of PP/HDPE woven bags and laminated bags. Management says the machine is unique in Taiwan because it can print lettering in the middle of the gusset of the woven bag.

Hao Yu Found Round the Globe

Another manufacturer providing whole-plant equipment for the production of PP woven bags is Hao Yu Precision Machinery Industry Co., which was established in 1980 in Taichung County, central Taiwan.

An ISO9002-certified manufacturer that in addition carries the CE mark, Hao Yu also specializes in providing geo-textile and wood/plastics composite products. The company says it is capable of rolling out a variety of machines for the production of low-denier foodstuff bags and high-denier woven bags.

The company's major product lines include twelve-shuttle jumbo circular looms, PP woven inner linear-inside lamination machines, flat-yarn high-speed extrusion machines, and wood/plastics composite extruding machines.

Hao Yu boasts it has exported whole-plant equipment to over 50 nations. Major export outlets include the Middle East, Africa, the Arabian peninsula, and Thailand. Recently the company has received an order for PP woven-bag whole-plant equipment from Zambia, which will be delivered at the end of April. The company will dispatch three well-trained workers to Zambia to help its customer install the equipment and launch trial-run operations.

The company focuses on the production of high-end products and innovative high-added-value machines. "Our PP woven-bag machine produced bags with tension-resistance five times stronger than those made by rival domestic producers, " says Hao Yu president Chi Ching-yao. "Because of our persistence in producing high-quality products, over the past several years we have won many government bids in our home market."

The company says it has a five-person in-house R&D department in charge of developing its innovative machine models. "In addition to developing brand-new models featuring sophisticated functions, we also pay much attention to the quality of our products in every detail. For instance, we import expensive bearings from industrially advanced nations."

Chi says his company has won a solid reputation for the production of plastic woven-bag machines in the international marketplace. "Our machines have proven reliability, and many customers say they are still using the machines we produced some two decades ago, " Hao boasts. "Thanks to this reliability, we have established such good relations with customers that they often help us find new clients."

Recently the company has been concentrating on the development and production of environment-friendly machines that are capable of producing woven-plastic materials used in protecting hill slopes from collapse.

Hao Yu's wood/plastics composite extruding machinery is one of the company's best-selling product lines. The machine can extrude wood/plastic composite decorative trims for home furnishing industry. "The decorative trims are moisture- and fire-proof, " says Chi. "Seeing the promising prospects of the composite decorative trims, we have alloted a section of our production facility to roll out the promising products by way of our machines.

The company boasts the woven-plastic materials produced with its machines have passed stringent inspection and testing from academic units, including National Taiwan University of Science and Technology, National Pingtung University of Science and Technology, and Chung Yuan Christian University.

Tai Shin a Name That Means Quality

Specializing in the production of extrusion lines and pelletizing equipment, Tai Shin Plastic Machinery Co., Ltd. Is focusing on price-competitive machines, rather than expanding product lines.

At present Tai Shin's major product lines include extrusion lines for flexible hoses reinforced with spiral yarn inserts, PVC (polyvinyl chloride) pelletizing plants, co-extrusion lines for soft-rigid spiral-wound pipes, twin-screw extrusion lines for PVC pipes and profiles, and extrusion lines for spring-wire hoses.

The co-extrusion line can produce soft-rigid spiral-wound pipes of two inches in inner diameter. "The machine is capable of rolling out 1.5 meters per minute, three times faster than the same model produced by other domestic manufacturers, " boasts Tai Shin general manager Gordon Chang.

To keep products at a high-level quality standard, the company imports top-grade parts and components from industrialized nations. The company has an in-house R&D department to develop innovative products. For instance, the company boasts its extrusion line for spring-wire hoses is unique in Taiwan. "The line is capable of producing one-piece spring-wire enhanced hoses without worrying about fracture, " says Chang.

At present the company exports 90% of its output to overseas markets, including Brazil, Argentina, Egypt, Saudi Arabia, the Middle East and Southeast Asia.

Chang boasts his company has received orders to fill production lines up to the end of July. "I estimate our sales for the entire year will grow by over 30% from last year's level because of the global economic recovery, " says Chang.

Chang says his company won't pursue expansion of quantity but quality. "It's meaningless for us to expand production capacity because we are small in size, " explains Chang. "But we will put more emphasis on producing high-quality and innovative products to draw customers' attention from the world over."

Recently the company has been speeding up the pace of development of its corrugated pipe-extrusion line, which it intends to introduce to the international marketplace in the middle of this year. Prototypes were on display at the Taipei International Plastics & Rubber Industry Show staged March 18-21 at the Taipei World Trade Center.

A Name to Remember

Jing Fang Machinery Co., Ltd., established 16 years ago, specializes in the production of high-efficiency, high-precision, and user-friendly plastic-processing machines.

The company's major product lines include laminating machines, and rotogravure printing presses (2-12 colors or 4-8 colors). The company boasts it is capable of rolling out two printing presses in three or four days.

With an in-house research and development department, Jing Fang concentrates on developing innovative products to meet customers' special demand. The company mainly exports its machines to Southeast Asia and mainland China, in addition to domestic sales.

"Since our establishment, we have been making all-out efforts to upgrade our machines by elevating the operating speed so that they can perform with high efficiency, " says Dein Huang-yu, president of the company.

The company's laminating machine is applicable for such materials as PP, PE, cellophane, aluminum foil, and paper. Maximum machine velocity reaches 200 meters per minute.

Although some developing nations such as mainland China have begun production of plastic processing machines, Dein says his company has no fear of it and will continually develop more sophisticated products to get rid of price competition from the newcomers of the developing nations.

The company boasts its machines are equipped with high-precision electric systems imported from Japan. "The state-of-the-art electric systems make our machine do such precise operations as material feeding and cutting, " Dein says.

Wei Sheng Crushes the Competition

Wei Sheng Machinery Industrial Co., Ltd., founded in 1991, specializes in the production of powerful, quiet-running crushing machines. The company boasts it is capable of rolling out quite a lot of peripheral equipment for the plastic processing machines.

With over a decade of development, the company has developed many practical machines to fit the need of the plastic processing industry, including silent granulator, claw-tool-type muffing crushing machine, instant crushing and recycling machine, waste recycling devices for vacuum forming products, universal powerful crushing machine, double-axle strong shredder, and vertical mixing blender.

With a workforce of 15, Wei Sheng is capable of rolling out 20 crushing machines per month. "Although our machines are medium and small in size, they are a must-to-buy item for the plastic processing machines, " says company president Lee Ta-wei.

Lee says his company has paid much attention to elevate the safety degree of the machines in operation. For instance, the company's muffing crushing machine is equipped with a safety device that can automatically stop the machine when it is improperly operated.

The company says its products are mainly sold to overseas markets, including the Middle, Southeast Asia and Europe.

Contact information on companies covered by the article:

1.

Hao Yu Precision Machinery Industry Co.

Address: No. 290, Haiwei Rd., Chungher Village, Lungching Hsiang, Taichung Hsien, Taiwan.

Tel: 886-4-2630-3998

Fax: 886-2630-1410

Website://www.green-tec.com.tw

E-mail: haoyu@ms12.hinet.net

2.

Tai Shin Plastic Machinery Co.

Address: No. 27, Chungcheng Rd., Minhsiung Industrial Park, Chiayi Hsien, Taiwan.

Tel: 886-5-213-2233

Fax: 886-5-213-2231

Website://tspm.com.tw

E-mail: tspm@ms14.hinet.net

3.

For Dah Industry Co.

Address: No. 48, Chungshan Rd., Minhsiung Industrial Park, Chiayi Hsien, Taiwan.

Tel: 886-5-221-5139

Fax: 886-5-221-9259

Website://fordah.com.tw

E-mail: fordah@ksts.seed.net.tw

4.

Jing Fang Machinery Co.

Address: No. 30, Lane 221, Jenhwa Rd., Tali, Taichung Hsien, Taiwan.

Tel: 886-4-2491-0016

Fax: 886-4-2491-0013

E-mail: jing.fang@msa.hinet.net

5.

Wei Sheng Machinery Ind. Co.

Address: No. 3, Alley 36, Lane 64, Tzuchiang 3rd., Wuchi, Taichung Hsien, Taiwan.

Tel: 886-4-2639-9998

Fax: 886-4-2639-3618

E-mail: breaker@ms23.hine.net

Website://www.weisheng.com.tw

©1995-2006 Copyright China Economic News Service All Rights Reserved.